High-Performance Membrane Materials Prepared by Shear-Driven Aggregation of Graphene Oxide/ Poly (vinylidene fluoride) Binary Colloids

This project aims to fabricate membrane composite materials by controlling the interaction and aggregation of graphene oxide/PVDF binary colloids, to be applied in the packaging field and lithium-ion battery separator.

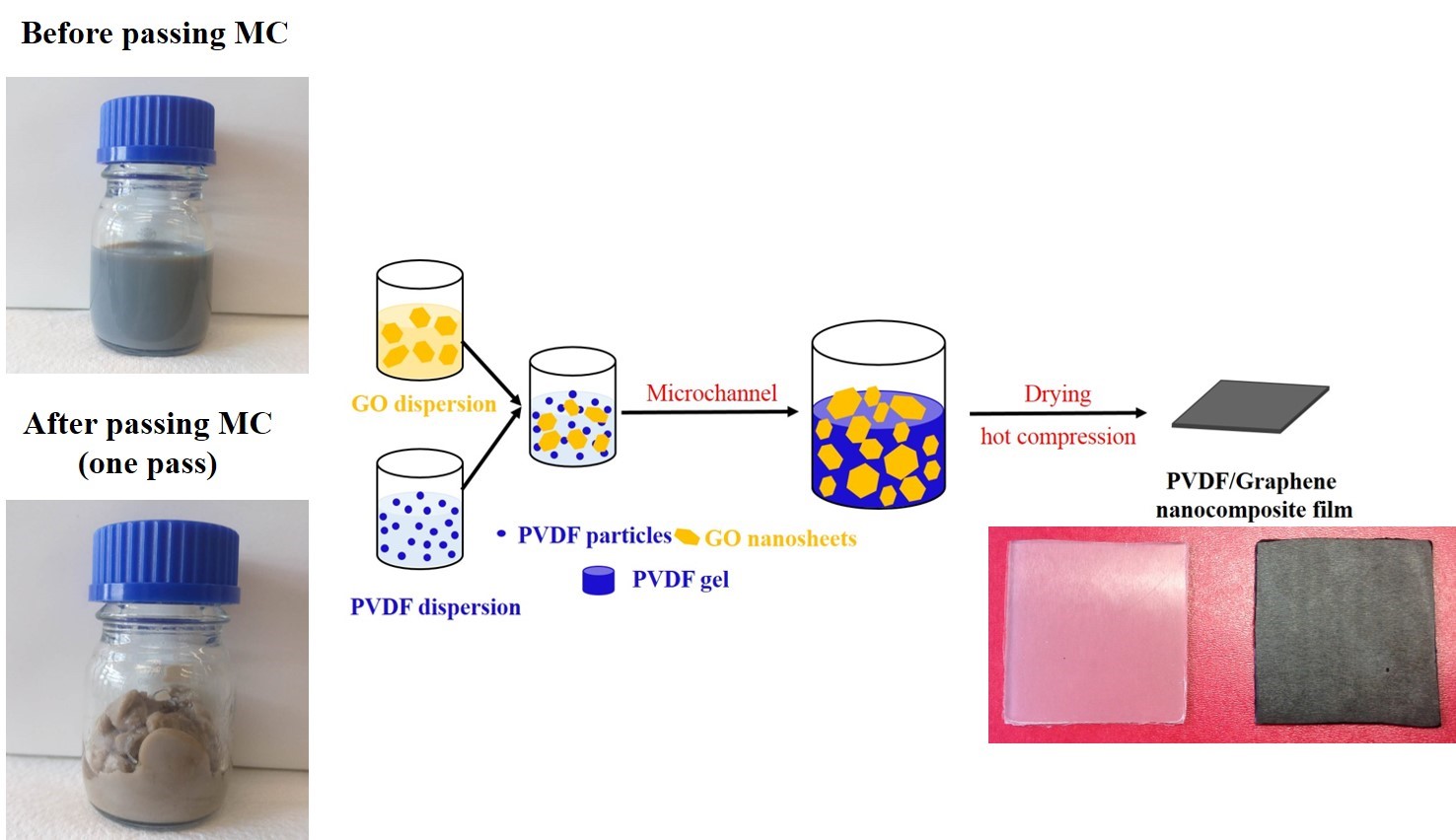

Polymer nanocomposites based on inorganic nanofillers (e. g., Graphene, SiO2, and TiO2) have aroused extensive research interests in the past decades because of their fantastic properties and wide range of applications. In particular, graphene, a single-atom-thick form of two dimensional sp2 bonded carbons, has triggered numerous studies due to their Young’s modulus, outstanding thermal conductivity, and high aspect ratio. Hence, graphene is one of the most promising additive to fabricate multifunctional polymer nanocomposites. However, pristine graphene can’t be used directly as nanofillers due to its high cost and lower compatibility with polymer matrix. Thus, most research have focused on the polymers with graphene oxide (GO). GO, a derivative of graphene, contain numerous oxygen functional groups (e. g., –OH, –COOH, and epoxide) and can be easily dispersed in water to form a stable colloid. GO has been incorporated into various polymer matrix, such as polystyrene (PS), polymethyl methacrylate (PMMA), poly (vinylidene fluoride) (PVDF), and polyurethane (PU). The aim of this project is to use an unconventional and simple method to fabricate polymer nanocomposites with high mechanical, thermal and barrier properties. The idea is to mix the polymer colloidal dispersion and GO colloidal dispersion to form a homogeneous dispersion, then the obtained dispersion is used for the shear-driven aggregation to get the polymer nanocomposites. (See in picture) In order to understand the aggregation mechanism, we investigate the effect of GO sheets on the shear-driven aggregation of PVDF colloidal dispersion under different conditions, including the concentration of GO, the shear time, and the role of pH, which also offers the opportunity to know how the GO sheets affects the final properties of composite materials.

Contact Person: Xinxin Sheng